What Are Tennis Shoes Made Of?

Tennis shoes are made of various parts and each part uses one or multiple materials. It is maybe not the first thing you ask or when you shop for shoes to play tennis. However, it is useful to educate yourself on the different components of tennis shoes to have a more in-depth look into the technology behind them and to become better at choosing the right tennis shoes for you.

A quick response would be: tennis shoes are made from materials like leather, plastic, liner, EVA… They incorporate important parts like the midsole for support, the outsole for traction and durability, the upper for flexibility and comfort, the tongue for a good fit, the cushioning for comfort and shock absorption, and the lacing to adjust the tightness.

It is similar to a running shoe except that tennis shoes need more shock absorption and stability because of more multidirectional movements with abrupt stops and rebounds. This is why tennis shoes provide more support and traction.

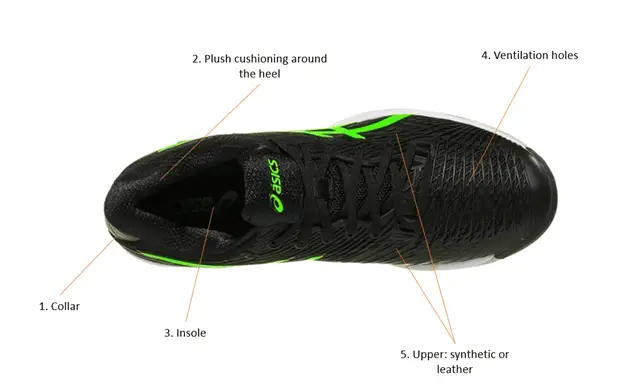

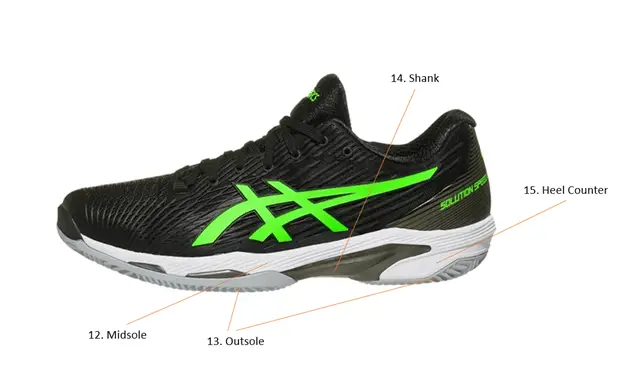

Anatomy of a Tennis Shoe

This is the anatomy of a tennis shoe.

- Collar

- Cushioning

- Insole

- Ventilation holes

- Upper

- Toe guard

- Toe box

- Vamp

- Laces:

- Eyelets

- Tongue

- Midsole

- Shank

- Outsole

- Heel counter

- Tread patterns

Materials Used in a Tennis Shoe

A tennis shoe isn’t made from a single material. But each part of the shoe is made from a suitable material to maximize its performance. Using the anatomy above, we can consider the most important components as follows.

1. Upper

The upper is the covering part of the shoe. It needs to be flexible, breathable and it should give the player the best possible fit to avoid feet movement inside the shoes.

Materials: Breathable mesh, leather, geomembranes liner. plastic…

2. Insole

The insole is the sole inside the shoes where the footrests. It should be comfortable and responsive to the footprint.

Materials: Usually made from foam, gel, cork, or leather

3. Midsole

The midsole is the sole where all the support technology is built. It is thicker and made from lightweight and innovative materials.

Materials: Most common are closed-cell foam called ethyl vinyl acetate (EVA) and polyurethane.

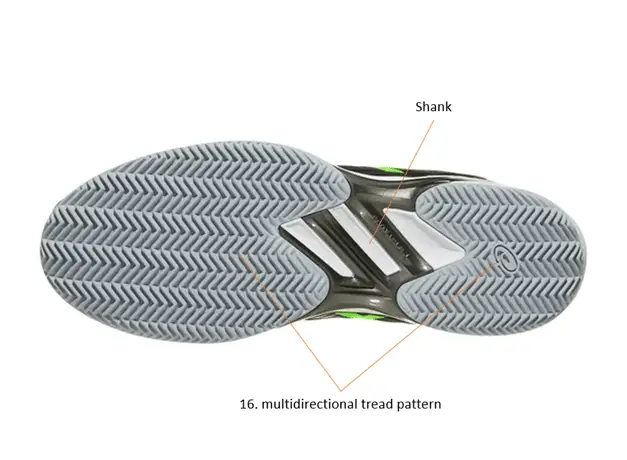

4. Outsole

The outsole is the bottom sole of the shoe in contact with the ground. In tennis, it is required to provide great amounts of traction and durability, since the movements are abrupt and occur in all directions possible.

The outsole contains a tread pattern to achieve the traction required.

Read more here: Are Tennis Shoes Slip-Resistant?

Materials: Rubber, polyurethane, or PVC compounds.

5. Toe Guard

The toe guard is the protection of the toe box. It helps the toe box maintain its shape and gives enough room to the toes even running or when sliding on the court.

Materials: Rubber or PVC.

6. Shank

The shank is a sturdy piece in the midfoot below the arch of the feet. It needs to be stiff to support the feet and prevent torsion or flexion. It is very useful for people with plantar fasciitis.

Materials: Thermoplastic polyurethane

7. Heel Counter

The heel counter is a rigid support at the back of the foot incorporated in the upper. It helps support the heels and supplies more stability in backward movements that happen a lot in tennis.

Materials: Thermoplastic polyurethane (Commonly known as celastic)

8. Tongue

It is a loose part of the upper located under the laces. Its role is to protect the feet from rubbing against the lacing system and to provide greater fit and comfort.

Materials: PU foam, leather, plush.

9. Lacing

The lacing system is important to adjust the tightness of the shoes and to prevent them from breaking loose.

Materials: Nylon, polyester, polypropylene, cotton…

How Are Tennis Shoes Made?

Most tennis shoe brands outsource the creation of their products in eastern countries like China, Malaysia, India… The main reason is obviously the cheap labor cost. However, another good reason is that these countries have, after years of experience, mastered the processes, which now have the ability to produce more quantities of shoes with great quality.

1. Preparation

Fabrics are cut into different parts of the shoe. The vamp die is the tool responsible for cutting the webbed material. This process is done manually. The worker tries to make the tightest possible cuts to maximize the used material.

In addition, in this phase, small details of the shoe come together. For example, this is where the workers put on models and sizing stickers.

The special parts like the toe guard, the heel counter, the tongue, and the lacing are also designed and prepared using adequate materials.

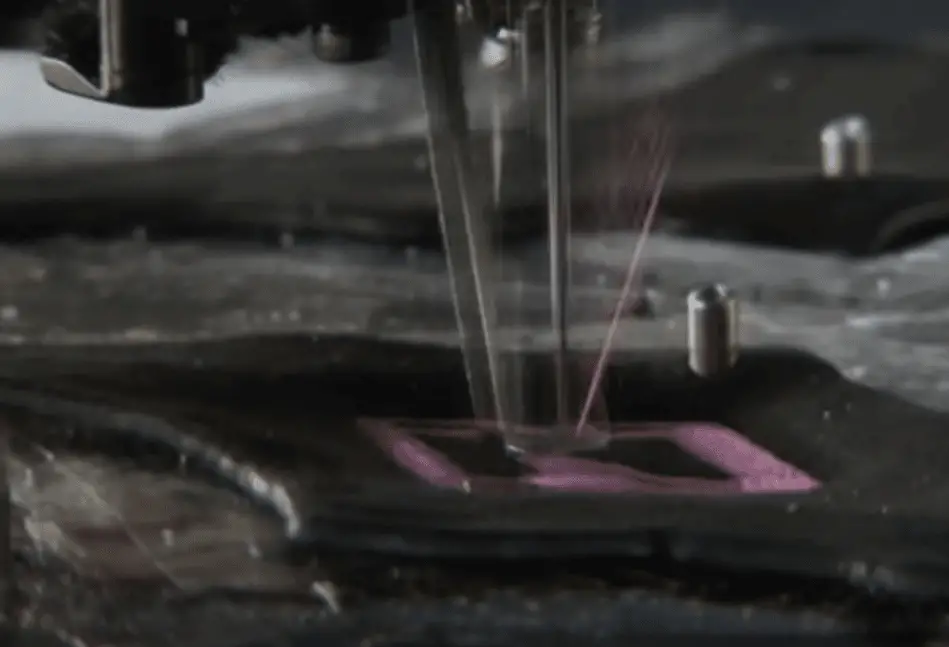

2. Initial Stitching

The initial stitching is the phase where the workers make flat machine stitching. The canvas of the upper is flat allowing millimetric precision in the stitching of the different parts. For example, the upper might be a single layer or a stack of multiple layers like a breathable mesh, a plastic cover, the logo, and other prints.

3. Hand stitching

Manual stitching is important because errors might happen in the previous phase and they need to be corrected by hand. In addition, the workers now bend and stitch the upper, and move it to the shoe last, to give it its final form like on afoot.

4. Assembly

This is the phase when the shoe construction is finalized. The sole, which contains the midsole and the outsole, is heated, along with the upper. Then both parts are permanently bonded using powerful glue and a hydraulic press machine.

Finally, the workers inspect the shoes and if everything is good, they pack them in a shoebox.

Tests Performed on New Tennis Shoes

Before releasing the final products, most companies run in-house tests using qualified people and machines. The goal is to question the shoes cushioning, flexibility, support, and durability.

1. People testing

To run tests, nothing beats real people’s feelings. For example, a sample of 20 or 50 shoes can be dispatched on a group of athletes to see how it performs after some time. Then, they gather the data to analyze the pros and cons to better optimize their shoe.

You can also perform a test on a new shoe by yourself using a three-point approach:

- Heel counter rigidity: by testing the firmness of the heel counter

- Torsional rigidity: by twisting the forefoot around the axis of the shoe

- Flexion stability: By flexing the forefoot like when you step on your toes.

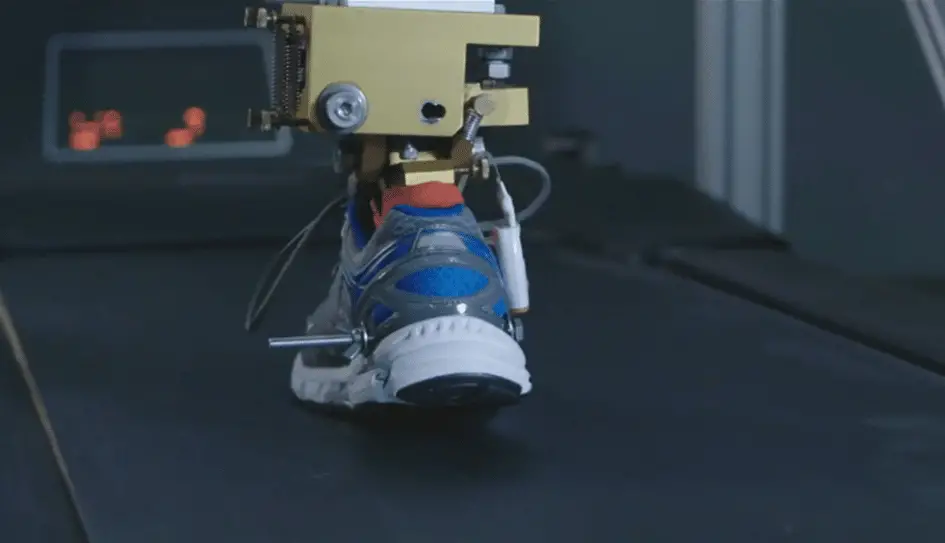

2. Machine testing

Machine tests are also efficient to have a quick response on the quality of the materials and the build.

Runner’s World, a famous sports magazine, uses a couple of tests in their lab to review athletic shoes.

For cushioning: They use a machine called an impact tester to measure how soft or firm each shoe is underfoot.

For flexibility: They use a machine that bends the shoe by 45° heel-strike to toe-off.

Some companies have gone a long way to innovate brilliant technology. As an example, a company called Heeluxe created a time machine to test your shoes. It basically lets you see how they will look and perform in the future.

By using, the machine, you can simulate 3 months of running in only 3 days.

The outsole, midsole, insole, and upper all break down like they would in the real world.

To Wrap it Up

In today’s highly commercial world, people are not only interested in the materials and the performance of tennis shoes, but they want attractive designs and beautiful colors. This is why the brands are nowadays focusing more on the marketing aspect of tennis shoes. Nevertheless, we have to salute the progress made to achieve excellent performance on the court.

Read Also: